Description

The bell is a musical instrument which, with the percussion of a sistro, produces only one note. The bell was a means of communication and was used mainly for naval or religious purposes. In our land, the bell was introduced from the West and replaced the iron semantron in the churches.

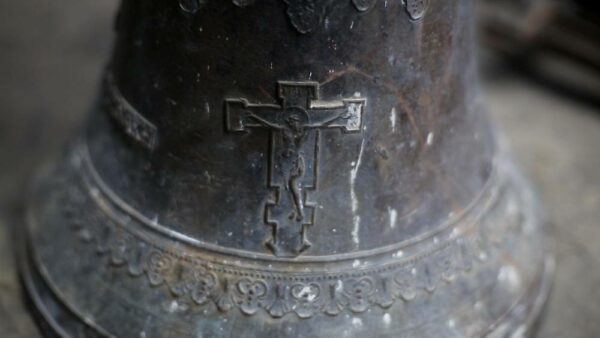

Metal casting is required to make a bell. Melting of the metal alloy and casting it in a specially made mold. The mold consisted of two parts, the inner, i.e. the male and the outer, i.e. the female. It was made of soil and took fifteen days to dry. The male mold gave the inner shape of the bell. In the female mold, which gave the external shape, the bell maker formed the bells’ decoration that differed according to the requirements of the customer. The final step in creating the bell mold is to bake it on low heat for three whole days.

After the creation of the mold was completed, the bell maker melted the metal alloy and cast it into the mold. The basic elements of a bell alloy are copper and tin.

The metal needed a day to cool. Then, after the bell was removed from the mold, it was ground and polished. Finally, the sound of the bell was checked. If a bell did not have the right sound, clear, loud and the right note, then the bell should be destroyed and rebuilt.